YINTONI UQINISEKISO LOMNTU?

Yintoni i-Induction Hardening?

Ukwenziwa lukhuni kwe-induction yindlela yokucima esebenzisa umgaqo wokungeniswa kwi-electromagnetic induction ukwenza i-workpiece isike imigca yemagnethi yomhlaba kwindawo etshintshanayo yamagnetic kwaye ivelise umsinga owenziweyo kwindawo yentsimbi. Ngokwempembelelo yesikhumba sokutshintshana kwangoku, umphezulu wecala elivuthayo lifudumala ngokukhawuleza ngendlela ye-eddy yangoku kwaye emva koko i-induction quenching ngokukhawuleza.

emva kokuba umatshini wokufudumeza igqiba inkqubo yokufudumeza kunye nokucima, iindawo zentsimbi umphezulu wobunzima buphezulu, undoqo ugcina iplastiki elungileyo kunye nokuqina, ubonisa ubuntununtunu obuphantsi, ngoko ke ukuqina kwempembelelo, amandla okudinwa, kunye nokumelana nokunxiba kuphuculwe kakhulu. Ngenxa yexesha elifutshane lokufudumeza, i-oxidation yomphezulu, kunye ne-decarburization yamalungu amancinci, xa kuthelekiswa nolunye unyango lobushushu, izinga lokwaliwa kwamalungu liphantsi kakhulu. Kwakhona ukukhetha i-coil yokufudumeza efanelekileyo yokufudumala idlala indima ebalulekileyo kwintsimi yonyango lokufudumala kwetsimbi.

Kutheni usebenzisa inkqubo yokuqiniswa kwe-induction?

Ukucinywa kwe-induction yinkqubo apho imisinga ye-eddy iveliswa kwi-workpiece yesinyithi ngokungeniswa kwe-electromagnetic kwaye i-workpiece ishushu. Xa kuthelekiswa netekhnoloji yokufudumeza kwentsimbi eqhelekileyo, itekhnoloji yokucima i-induction inezi nzuzo zilandelayo:

1. Ubulukhuni bentsimbi yomphezulu womsebenzi buphezulu. Ubunzima bomphezulu wesixhobo sokusebenza esiqiniswe kukufudumeza okuphakamileyo kunye nokuphakathi okuphakathi kwe-2 ~ 3 HRC ephezulu kunokucima okuqhelekileyo. Ukuqina kwayo kwempembelelo yesinyithi, amandla okudinwa, kunye nokumelana nokunxiba kuphuculwe kakhulu. Ubomi benkonzo yentsimbi yokusebenza yensimbi inokwandiswa kakhulu ngokucinywa kwe-induction.

2. I-workpiece yesinyithi ayibandakanyi ukufudumeza, ngoko ke ngokuqina kwe-induction, i-workpiece iyonke i-deformation incinci;

3. Ixesha lokufudumeza kwentsimbi yokusebenza lifutshane, inani le-decarburization ye-surface oxidation lincinci;

4. Umthombo wokufudumeza usebenza kwindawo yokusebenza yesinyithi, isantya sokufudumala kunye nokusebenza kakuhle kuphezulu;

5. Isakhiwo sesixhobo sokucima i-induction sixinene ngakumbi kunesixhobo sokufudumeza esiqhelekileyo sesinyithi, kulula ukusebenza.

6. Umatshini wokwenza lukhuni wokufakelwa uqaphela ukusetyenzwa ngoomatshini kunye nokuzenzekela kunyango lobushushu, ukonga iindleko zabasebenzi.

7. Itekhnoloji yokuqinisa itekhnoloji yokuqina komphezulu ingasetyenziselwa ukufudumeza kokungena kunye nonyango lobushushu bekhemikhali.

Indlela yokukhetha inkqubo efanelekileyo yokwenziwa Ukuqina?

Inkqubo yokwenziwa lukhuni kwe-induction ineendlela ezininzi zokufudumeza kwaye zonke zineendawo zokufudumeza ezifanelekileyo.

1. Indlela yokuqinisa ukufudumeza ngexesha elinye:

Ukufudumeza kwe-induction ngexesha elinye okanye ukufudumeza kwangexesha elifanayo yeyona ndlela ixhaphakileyo yokuqina. Xa le ndlela isebenzisa iityhubhu ezimbini ezixande ezijikeleze umphezulu womsebenzi wokufudumeza okujikelezayo, ngokuqhelekileyo ibizwa ngokuba yi-Single Shot.

Inzuzo yale ndlela yokufudumeza i-induction kukugqiba yonke imisebenzi yokufudumeza indawo yokusebenzela ngexesha elinye. Ngoko ke, ukusebenza kwayo kulula, imveliso iphezulu, ifanelekile ukufudumeza indawo yokusebenza ayinkulu kakhulu. Ukufudumeza i-workpiece yendawo enkulu, yamkele indlela yokufudumeza ngexesha elinye, ifuna amandla amakhulu kunye neendleko eziphezulu zotyalo-mali.

Eyona mizekelo ixhaphakileyo yokuqina kokufudumeza okwexesha elinye ziigiya zemodulus ezincinci neziphakathi, i-CVJ imivalo yentsimbi emile okwentsimbi, imidyarho yangaphakathi, amavili okuthwala, amavili axhasayo, izikhonkwane zentwasahlobo zamagqabi, izitsala, iziphelo zevalvu, i-valve rocker arm arcs, njl.

2. Ukuskena indlela yokwenziwa lukhuni:

Xa indawo yokufudumeza i-workpiece inkulu, i-induction i-induction inikezela amandla amancinci, le ndlela isetyenziswa rhoqo. Kule ndawo, indawo yokufudumala ebalwayo S ibhekisela kummandla oqulethwe yindandatho yokungeniswa. Ngoko ke, ukuxinana kwamandla afanayo, i umatshini wokufudumeza amandla afunekayo amancinci, ukukhuphisana umatshini wokuqinisa induction iindleko zotyalo-mali ziphantsi, zifanelekile kwimveliso encinci ye-batch induction yokuqina, imizekelo eqhelekileyo yintsimbi ye-piston enobubanzi obukhulu, i-corrugated roll, roll, pipeline ye-oyile, i-sucker rod, i-rail, isikhokelo sesixhobo somatshini kunye nokunye.

3. Icandelwana-ixesha elinye induction ukufudumeza indlela yokucima

Imizekelo eqhelekileyo kukuqiniswa kwee-camshafts ezininzi, ixesha ngalinye ukutshisa ikhamera enye okanye ngaphezulu, emva kokugqiba eli xesha lokucima ukucima, ukufudumeza enye inxalenye yecam, iigiya ziqiniswe izinyo ngezinyo nazo zinokubandakanywa kolu didi.

4. Icandelwana induction ukuskena indlela yokucima

Imizekelo eqhelekileyo ziishafu zevalve yerocker okanye isantya esitshintshayo sokwenziwa lukhuni, apho iindawo ezininzi zeshafti ziskenwa ukucinywa kwe-induction, ububanzi bokucima bunokwahluka, kwaye ukucinywa kwezinyo ngokuskena kwakhona kunokuqukwa kolu didi.

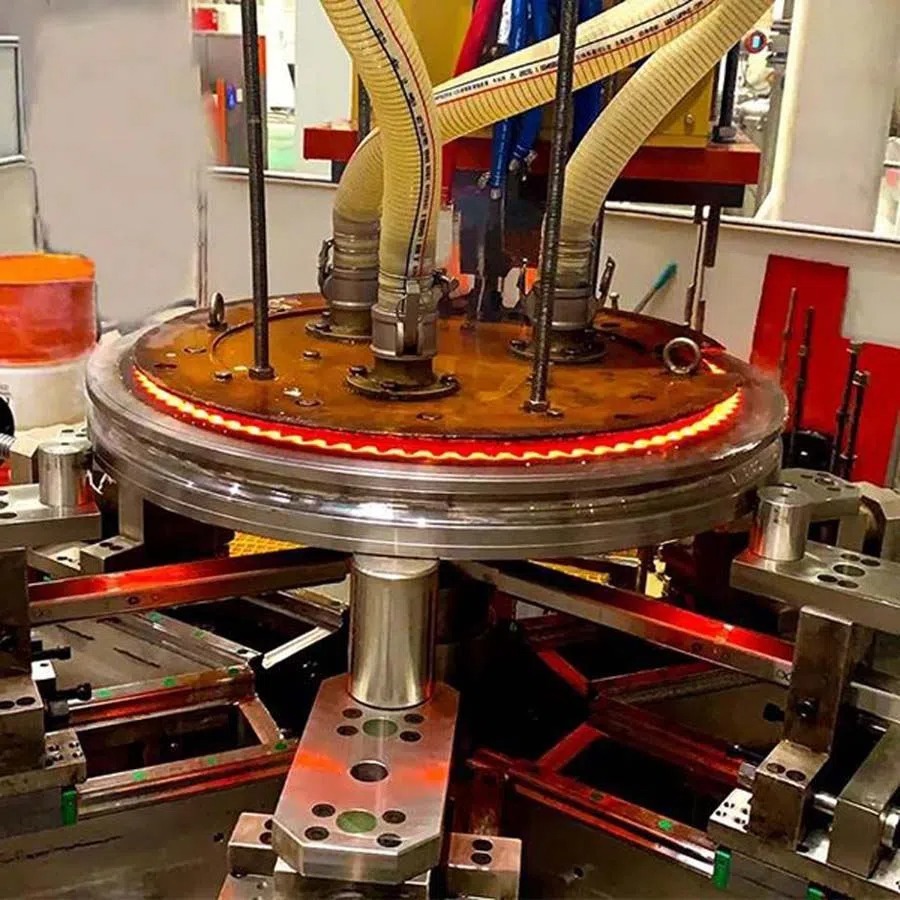

5. Ukufudumeza kwe-induction kunye nokucima kulwelo

Induction ukuqina quenching kulwelo, kuthetha i coil induction kunye nomphezulu wokufudumeza umphezulu untywiliselwa kulwelo lokucinywa kwe-induction, lufudunyezwe, ngenxa yoxinaniso lwamandla omphezulu wokufudumeza likhulu kunomlinganiselo wokupholisa wokucima ulwelo olujikelezileyo. Ngoko ke, umphezulu uyatshisa ngokukhawuleza. Xa i-inductor ivaliwe, umphezulu we-workpiece unzima ngenxa yokufunxa ubushushu be-workpiece core kunye nokupholisa ulwelo lokucima.

Le ndlela ifanelekile ngokubanzi kwi-workpiece yensimbi efuna izinga lokupholisa elingaphantsi. Xa i-workpiece ifakwe emoyeni kwaye i-coil induction inikwe amandla, ubushushu bomhlaba bufunxwa ngumbindi we-workpiece. Xa isantya sokupholisa somgangatho oshushu sikhulu kunomlinganiselo obalulekileyo wokupholisa, i-workpiece ilukhuni, efana nokucima kwi-liquid.

Ngawaphi amacandelo enkqubo yokuqiniswa kwe-induction?

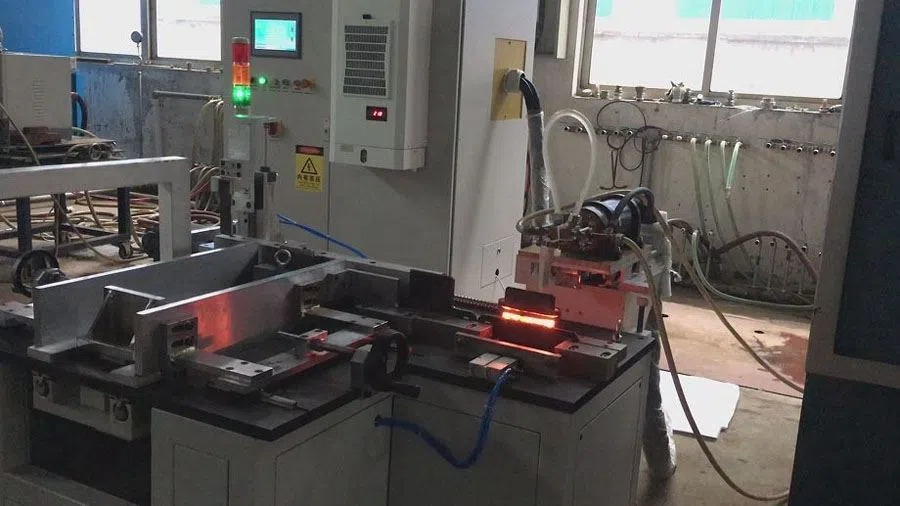

Ukuqulunqwa kokupheleleyo Umatshini wokucima uqeqesho ngokubanzi ibandakanya unikezelo lwamandla okufudumeza induction, isixhobo somatshini wokwenza lukhuni kwe-CNC, i-coil yokuqinisa i-induction, kunye nenkqubo yokujikeleza kwamanzi okupholisa kunye nokucima inkqubo yokujikeleza kolwelo.

Abavelisi bezixhobo zokufudumeza zangoku, inxalenye enkulu yokukwazi ukwenza iiseti ezipheleleyo zezixhobo zokwenziwa lukhuni kunye neprojekthi ye-turnkey, umsebenzisi ukusuka ukuze acuthe umjikelo wemveliso, kwaye athintelwe ngenxa yesebe lokubonelela ngeendlela ezininzi kwinkqubo yokulungiswa kweempazamo ayihambelani, kunye nokuguquguquka okude njengexesha. Ukunikezelwa kwezixhobo ezipheleleyo kunye neeprojekthi ze-turnkey ziye zaba yindlela yokhuphiswano kubenzi bezixhobo.

Lilonke, Njengomnye wabavelisi benkqubo yokwenziwa lukhuni kwe-induction e-China, siye sanceda amawaka emizi-mveliso yonyango lobushushu ukufumana izisombululo ezifanelekileyo zonyango lobushushu lokungeniswa, ukuze kuqinisekiswe inkqubo efanelekileyo yokuqiniswa kwenkqubo yokucima. Ungandivumela ukuba ube nemizobo yamalungu akho aqinileyo, izinto, ubulukhuni, kunye nobunzulu bezicelo, kwaye sinokukunika iingcebiso zobugcisa ezihambelanayo kunye namaphepha ocaphulo. Enkosi.

I-Induction Ukuqina Kwenkqubo Yokucima Iimeko zeSicelo esiKhethekileyo

1. Umdyarho othe nkqo othe nkqo we-CNC wokuqalisa ukucima inkqubo yokucima

2. Inkqubo ye-Chain Plate Induction Hardening System

3. Cantilever gear CNC induction umatshini lukhuni inkqubo

4. Wind Power Bolt Induction Ukucima kunye neTempering System Production Line

5. Iqokobhe le-shaft elungeleleneyo yangaphakathi yomngxuma wokungenisa ubushushu inkqubo yokuqina

6. Enkulu Mill Roller Induction Ukuqina